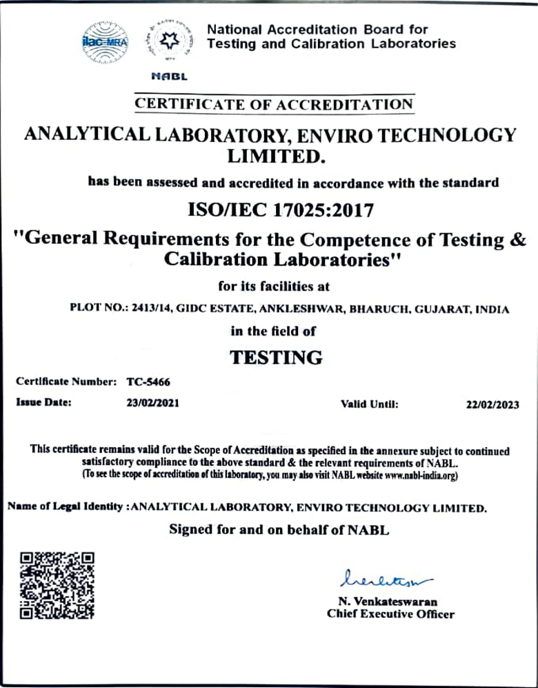

ABOUT ENVIRO TECHNOLOGY LIMITED

ABOUT ENVIRO TECHNOLOGY LIMITED

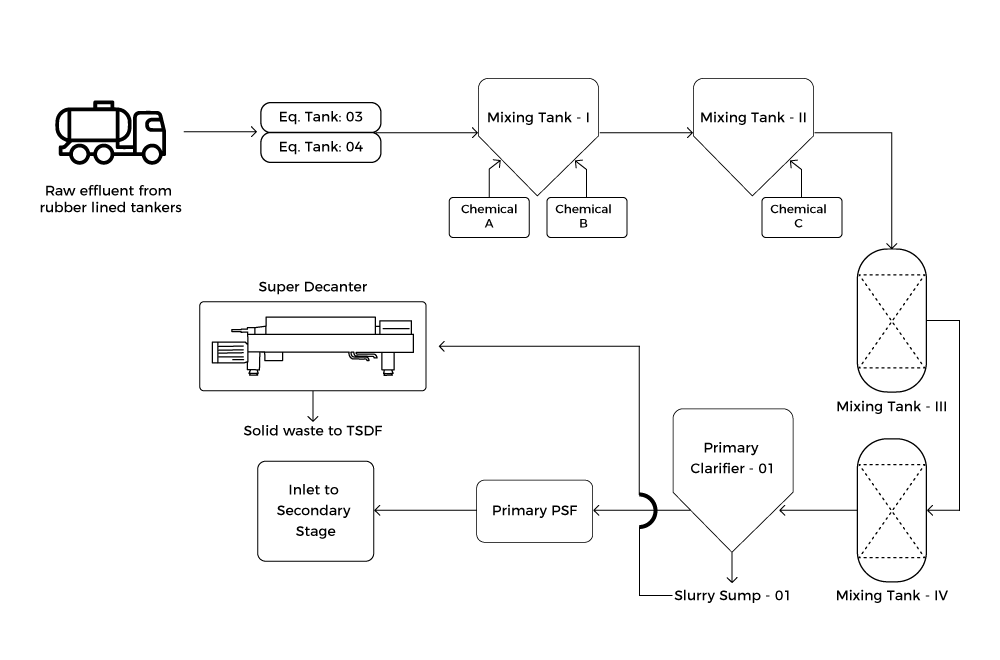

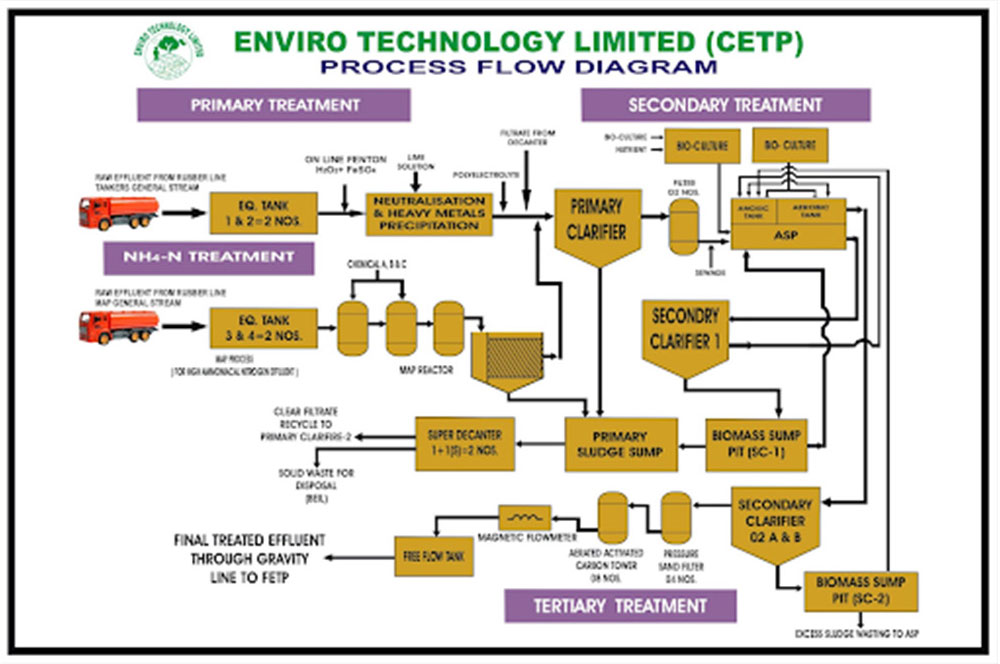

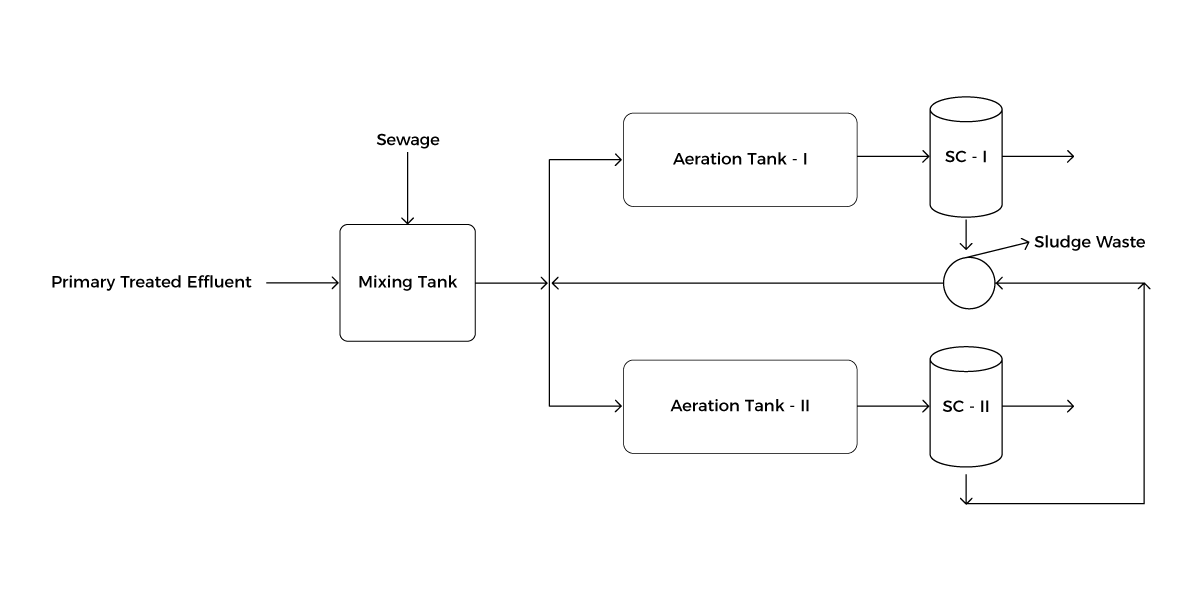

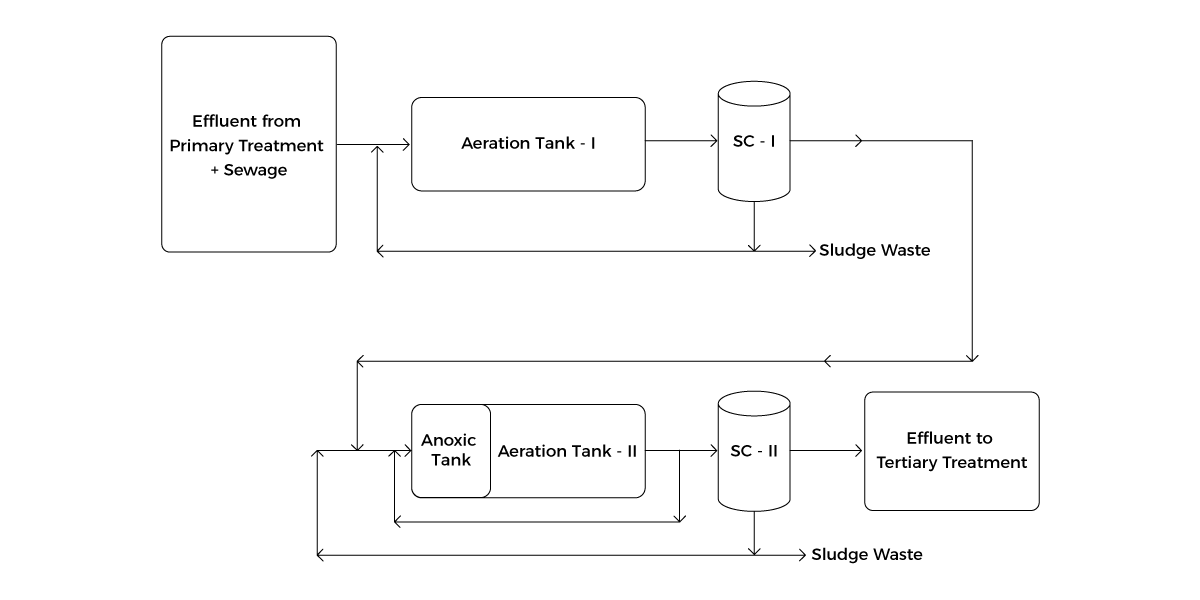

Enviro Technology Limited is operating a Common Effluent Treatment Plant (CETP) for more than 350 small scale industries located in the GIDC Industrial Estate of Ankleshwar. Raw effluent received from the member industries is treated, both chemically as well as biologically in primary, secondary and tertiary units at CETP. The process of effluent treatment is a continuous one.

ETL receives effluent from various types of small-scale industries like dyes & dyes intermediates, chemical, pharmaceuticals, etc

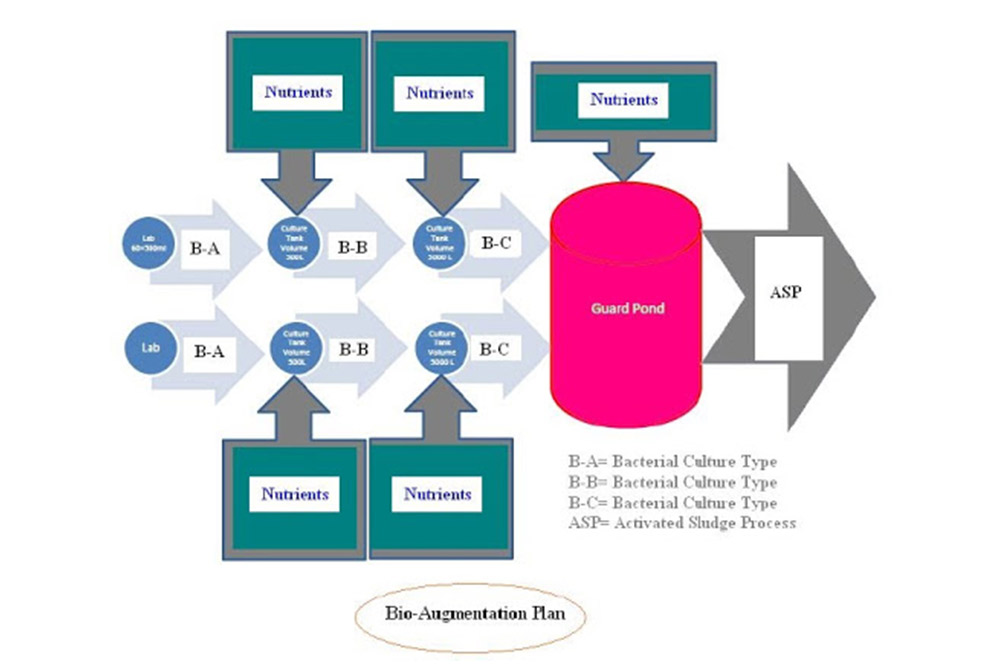

Enviro technology Ltd. is state of art CETP consisting of primary, Secondary, Tertiary and MAP treatment process.